- Have any questions?

- +61 424 178 561

- +61 3 9837 5203

- [email protected]

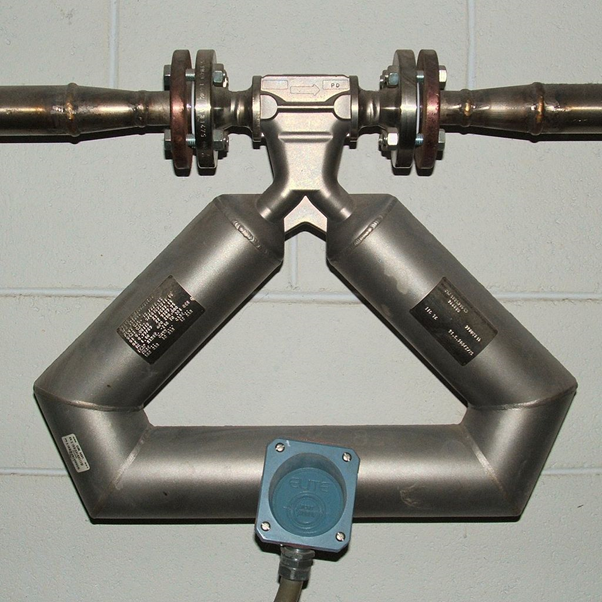

Coriolis Flowmeter

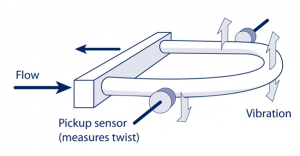

In a Coriolis mass flowmeter, the “swinging” is generated by vibrating the tube(s) in which the fluid flows. The amount of twist is proportional to the mass flow rate of fluid passing through the tube(s). Sensors and a Coriolis mass flowmeter transmitter are used to measure the twist and generate a linear flow signal.

Each Coriolis flowmeter has one or more measuring tubes which an exciter causes to oscillate artificially. As soon as the fluid starts to flow in the measuring tube, additional twisting is imposed on this oscillation due to the fluid’s inertia. Two sensors detect this change of the tube oscillation in time and space as the “phase difference.” This difference is a direct measure of the mass flow.

In addition, the fluid density can also be determined from the oscillation frequency of the measuring tubes. The temperature of the measuring tube is also registered to compensate thermal influences. The process temperature derived from this is available as an additional output signal.

Features:

- Universal measuring principle for liquids and gases

- Multi variable measurement – simultaneous measuring of mass flow, density, temperature and viscosity

- High measuring accuracy: typically ±0.2% o.r., optionally: ±0.05% o.r. (PremiumCal)

- Measuring principle independent of the physical fluid properties and the flow profile

- No inlet/outlet runs necessary