- Have any questions?

- +61 424 178 561

- +61 3 9837 5203

- [email protected]

Positive Displacement Flowmeter (Volumetric Flowmeter)

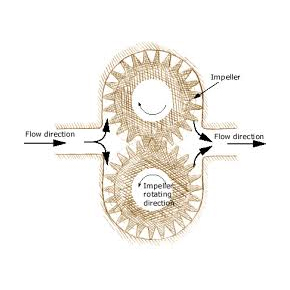

Positive displacement flowmeters are the only flow measuring technology to directly measure the volume of fluid that passes though the flow meter. It achieves this by trapping pockets of fluid between rotating components housed within a high precision chamber. This can be compared to repeatedly filling a beaker with fluid and pouring the contents downstream while counting the number of times the beaker is filled.

Rotor rotational velocity is directly proportional to flow rate, since the flow of fluid is causing the rotation. In electronic flow meters the rotating components contain magnets that activate various sensor options located outside the fluid chamber. Mechanical flow meters rely on the rotation to drive either a magnetic coupling or a direct gear train connected to the mechanical counter.

Features:

- High level of accuracy (0.5% as standard) higher level of accuracy available upon request

- Ability to process a large range of fluid viscosities <1 cP – >500000 cP

- Low maintenance

- High pressure capabilities

- Electronic and mechanical versions available

- Spare parts availability

Applications:

The industries where they are used in descending order are oil and gas, water and wastewater, chemical, power, pharmaceutical, food and beverage, pulp and paper, metals and mining and aerospace. Many positive displacement flowmeters are used in municipal water districts to measure residential water consumption. Considering an installed base of millions of houses and apartments with metered water service, this application represents perhaps one of the largest number of applications of positive displacement flowmeters worldwide.

Showing all 2 results