- Have any questions?

- +61 3 9837 5203

- sales@slentech.com.au

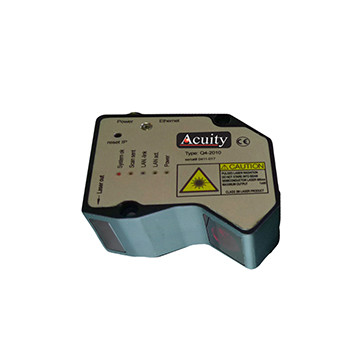

AR700 Laser Displacement Sensors

AR700 Series of Laser Displacement Sensor for measuring position and object dimensions employs triangulation measurement principles whereby it projects a beam of visible (or optionally, infrared) laser light that creates a spot on a target surface. Reflected light from the surface is viewed from an angle by a digital CMOS line scan camera inside the AR700 sensor. The target’s displacement is computed from the image pixel data. The AR700 boasts output speeds to 9.4KHz and resolutions (model dependent) as low as one sixth of a micrometer. The unit is very compact, measuring approximately 25 x 50 x 75 mm.

Road Profiling package for AR700-6 or -8. includes specialized optics, upgraded diode, bandpass filter and signal processing firmware optimized for use in high-speed longitudinal road surface profiling.

Hot Steel Slab Width & Thickness Measurement is done with dual AR700-50 Non-Contact Dimensional Measurement 0f continuously-casted steel. Laser sensors are commonly used in steel hot mills for an accurate, non-contact method of determining the position or dimensions of materials that are too hot to touch.

Features

- Measuring Range from 3 to 1270 mm

- Selectable speeds up to 9.4KHz (when using 3-Byte Binary Data format)

- A special trigger mode to initiate sampling via serial command or discrete hardware triggers

- Resolution of 0.005% (of the measurement span) for all models in this series

- The linearity specification is +/-0.03% of the sensor’s measuring span

- Standard serial and analog outputs