- Have any questions?

- +61 424 178 561

- +61 3 9837 5203

- [email protected]

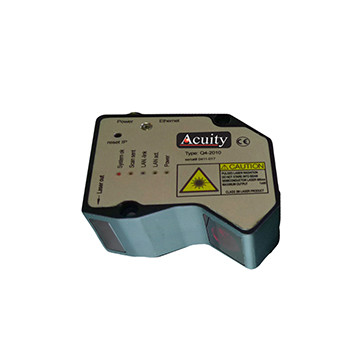

AP820 Non-Contact 2D Laser Scanners

AP820 Laser Profile Scanner use similar triangulation measurement principles. A laser line composed of many, closely-spaced laser spots, is emitted onto a surface. The image of this line is viewed at an angle by a two-dimensional CCD detector array. The AP820 laser scanners are more compact and lighter devices that are designed for use with engineered protective enclosures for tough industrial environments. Although capable of 100 scan lines per second, the AP820 boasts improved resolution and performance on dark surfaces and shiny targets.

The AP820 laser scanners have dynamic, auto-gain which adjusts laser power and sample integration time (shutter speed) which improves sensor performance on dynamically-changing surfaces. Changing surface reflections and orientations will not produce noisy measurements. Common applications include dimensional verification of heights, widths, radius of curvature, gap width, surface separation, part length, hole diameters, etc.

Download Datasheet

Features

- The two-dimensional contour profile is calculated by the scanner’s microprocessor from the pixel data from the diffusely-reflected laser line.

- The Accuprofile 820 laser profile sensor offers greater precision and high accuracy.

- The height distance profile is transmitted through Ethernet communications to a PC computer.

- Real-time 3D profiling is created by synchronising the position of the scanner with encoder inputs from conveyors, linear stages or robotic movements.

- A variety of models are specified, each to allow a different measurement range and field of view.

- The scanner’s sophisticated CCD detector affords the highest dynamic optical range, allowing these devices to measure almost any kind of opaque surface, shiny or matte, bright or dark.

- The sensor performs well on sharp edges and transitions without producing noisy results.