- Have any questions?

- +61 3 9837 5203

- sales@slentech.com.au

LVDT/LVIT

LVDT (transformer) and LVIT (inductive half bridge) sensors are proven, reliable measurement options for acquiring data on displacement and positions, featuring contact-free and low-wear acquisition and high possible measurement dynamics. High-quality materials are used to ensure extraordinary robustness and to provide decades of maintenance-free operation. These sensors are passive sensors (so-called AC/AC sensors) which require conditioning (carrier frequency) electronics to operate; either integrated in the displacement sensor or installed in a separate housing.

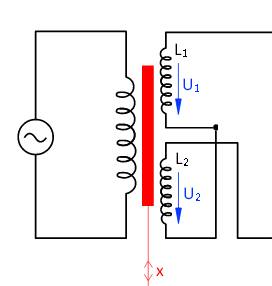

LVDT (Linear Variable Differential Transformer) consists of primary and secondary coils (beside each other or over and under, depending on the model) which are not connected electrically and which are coupled according to the transformer principle via a ferromagnetic core. The secondary coil consists of two coils (halves) which are wired inversely, the overall signal of which thus forms a “difference”.

The primary coil of the LVDT, supplied with an AC voltage, induces a voltage in the secondary coil. Because of the inverse wiring, in the center position of these coils (immersion core)the voltage is equal to zero. If the immersion core is shifted, the measurement voltage at the differential inductor changes proportional to the displacement.

A LVDT permits more favorable displacement-construction length relationships than, for example, LVITs and is less sensitive to external interference factors (e.g. greater temperature differences within the sensor range or changes in resistance in the measuring cable). The more elaborate construction leads to somewhat higher manufacturing costs.

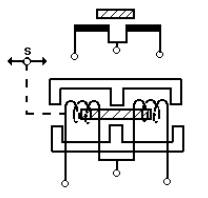

Electrically a displacement sensor according to the LVIT (Linear Variable Inductance Transformer) principle consists of a coil with a center pickup or two coils wired in series with each other. A ferromagnetic core which moves inside a coil (immersion core) changes the behavior (inductance) of the coil (halves) with the change of position. In the center position, it causes both coils to be influenced equally, thus exhibiting the same apparent impedance.

If the core is moved from its center position, the apparent impedances of the LVIT changes in both measuring coils inversely, which can be displayed on a connected conditioning electronic component proportional to the displacement. Inductive displacement sensors as LVITs are characterized by economical construction and thus, productivity, higher accuracy classes and lower temperature drifts can be achieved relatively easily.